Plastic Formwork Products For Construction Projects

TEPI Plastic Formwork Products Benefits

TEPI Polymetal shuttering products are made of recycled plastic with strong steel support frames. Our modular shuttering materials meet a range of construction and planning requirements, including those for walls, foundations, and columns and pillars with varying thicknesses and heights.

When compared to conventional steel, plywood and aluminium panels, our product's panels are especially light. Additionally, the plastic substance from which they are formed prevents the concrete from sticking, allowing for easy cleaning and reuse..

Our formwork products are reusable for more than 100 times when properly maintained

We are the leading manufacturers and suppliers of best shuttering products across India at a reasonable prices. We pride ourselves in being Environment friendly along with being one of the most cost effective alternatives for Steel, Ply and Aluminium Formwork. Our products have been supplied and used by major Contractors/Construction Companies across Bangalore and India.

TEPI offers formwork solutions for all areas of construction activity from heavy duty sectors like Highways, Bridges and dams, Water bodies and Aquariums and High-rise Residential and Commercial Buildings.

Column Formwork

TEPI column Formwork (Boxes) are a revolutionary solution in the field of construction designed and manufactured by TEPI Formwork. Their heavy-duty and large-dimension boxes are an excellent alternative to Mild Steel column shuttering.

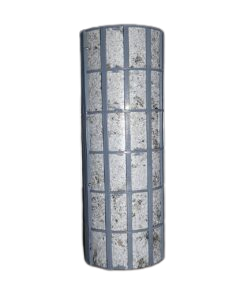

Circular Column Formwork

These specialized circular column boxes are designed to cater to the specific requirements of large dimension circular columns that were until now only possible to make using Mild Steel.

Slab Shuttering

Our Tepi slab shuttering comes in various sizes such as 2 X 8 feet, 4 X 4 feet, and 2 X 4 feet. The primary benefit of our slab panels is the ease and speed of laying them using the telescopic spans and laterals. With over 150 repetitions,

Beam Formwork

TEPI Beam Formwork (Bottom and Sides shuttering) are the ideal solution for ensuring perfect finishes, right angles, and even surfaces. Made of tubular frame structure, they provide superior strength and support for beam casting.

Adjustable Telescopic Lateral and Span

TEPI Adjustable Telescopic span and lateral are a versatile and sturdy solution for shuttering needs. With the ability to expand from 2m to 6m, they provide a wider range of options for shuttering design.

Retaining wall Shuttering

TEPI retaining wall shuttering is a versatile solution for various applications such as sheer walls and bridges. We specialize in manufacturing custom retaining walls with a thickness of 650mm and more, making them ideal for heavy infrastructural projects. .

Precast Mould

TEPI precast moulds are a cost-effective solution for expensive MS moulds, offering over 150 repetitions with perfect sizes and uniform finishes. With TEPI precast mould, you can deliver high-quality products, while saving time and money..

MONOLITHIC FORMWORK

TEPI’s MONOLITHIC FORMWORK offers an excellent solution for constructing leak-proof water bodies. Our custom-made water body moulds are suitable for large-scale projects like water storage tanks, fish ponds, and aquariums.

Raft Formwork

TEPI Raft Formwork products Panels are a versatile and cost-effective solution for construction projects involving large-scale raft floorings. We provide custom-made Raft Panels that can be later used for column footings, sheer walls, and retaining wall.

Crash Barrier Mould

TEPI concrete crash barrier mould is designed to provide a cost-effective solution for producing high-quality concrete barriers. These moulds are used in various road construction projects and offer excellent durability, strength, and longevity.

H Frame Scaffolding

H frame scaffolding is a popular type of scaffolding and is called so because of its shape. The frame is made up of vertical posts and horizontal crossbars, forming an H shape. The frame is stable, durable, and easy to assemble and disassemble.

Cuplock Scaffolding

Cuplock scaffolding is a popular and efficient scaffolding system that uses a locking mechanism to secure the ledgers and standards together. TEPI Cuplock scaffolding is made of high-quality steel, which makes it strong, durable and easy to assemble.

Adjustable Telescopic Prop Jack

TEPI Adjustable prop jack with different heads are the ideal solution for all kinds of construction needs. They can be used to support heavy loads and come in various sizes and load-bearing capacities. The heads are designed to fit different types of construction materials and structures.

Shuttering And Centering Material

The choice of plastic shuttering or centering material depends on the specific requirements of the construction project, including the type of structure, load-bearing capacity,

Raw Materials Used In TEPI Formwork

| DESCRIPTION | ISO STANDARD | TEPI – P1 | TEPI – P2 | TEPI – P3 |

| Material | Virgin Polypropylene | Recycled Polypropylene | Recycled Polymer Formwork | |

| Material Grade | SOLID – HD UHMW | Hollowgrid PP | SOLID – Aluminium Composite Polymer | |

| Thickness | 1-200mm | 12/14/18mm | 6/10/12/18/24/30mm |

| Density | ISO 1183 | .9 g/cm3 | .75 per g/cm3 | 1.2 per g/cm3 |

| Tensile Strength | ISO 527.1 | 26 Mpa | ||

| Breaking Strength | 36 Mpa | |||

| Ball Thrust Hardness | ISO 2039.1 | 50 N/mm2 | ||

| Shore Hardness | ISO 868 | 69 | ||

| Abrasion Resistance by sand slurry test | ISO – 15527 | 350-400 Rotations |

What Makes a Good Formwork?

Good formwork is essential in construction projects to create the desired shape and structure of concrete elements such as walls, columns, slabs, and beams. The quality of formwork significantly influences the overall success of a construction project. Here are key factors that contribute to making good formwork:

The factirs listed below are what your system of choice should have:

- Exceptional ability to support loads

All live loads, such as the weight of building occupants, traffic, vehicles, equipment, and other temporary elements, as well as dead loads, such as the weight of the concrete structure itself and other permanent loads, should be supported by the formwork system.

- Excellent capacity to maintain shape

To successfully maintain its shape, the formwork must be built stiffly and well supported by bracing and props.

- Watertight joints

To stop cement from seeping out of the joints, they must be firmly sealed.

- Causes no harm to the concrete

In case the formwork is detachable, it must to be designed in a way that allows different sections to be taken out without causing any harm to the concrete.

- Made from recyclable components

One effective way to reduce expenses and increase savings is by implementing a formwork system made of recyclable materials like steel and aluminum. It is also more environmentally friendly.

- Compact design

Lightweight formworks save time and labor since they are quicker and easier to move and assemble.

- Without distortion or warping

It must not deform or warp when exposed to the weather in order to guarantee maximum dependability.

Enquiry Now

For Latest Prices

Fill in the form. Our team will get in touch with you soon.